Optimize360°

Your Trusted Partner in

Operational Excellence

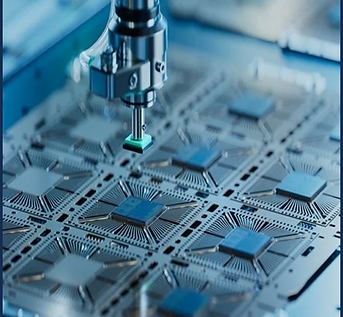

Safety First: Protecting People and Progress in the Semiconductor Industry

Safety is paramount in the electronic (semiconductor) industry. This is due to the extensive use of highly hazardous chemicals, intricate equipment, and complex processes. Prioritizing safety isn't just an ethical imperative; it's crucial for operational continuity, regulatory compliance, and protecting your workforce and the environment. As OSHA emphasizes, "Designing manufacturing processes to avoid or reduce workplace hazards early in a process adoption or a process change is one of the best ways to prevent injuries and illnesses."

The Bedrock of Safety: Comprehensive Employee Training

In the high-hazard electronic industry, employee safety training transcends mere compliance; it's the bedrock of sustained safety performance. Comprehensive training equips personnel with the knowledge and skills to recognize, assess, and mitigate the diverse chemical, physical, and ergonomic risks inherent in their work. It fosters a proactive safety culture where every employee becomes a vigilant participant in hazard identification and prevention.

Well-trained employees are more likely to adhere to safety protocols, correctly use personal protective equipment (PPE), and respond effectively in emergency situations. This reduces the likelihood of incidents, minimizing injuries, equipment damage, and production disruptions. Continuous and specialized training, tailored to specific roles and evolving processes, ensures that safety knowledge remains current and relevant. Ultimately, investing in thorough and ongoing employee safety training cultivates a competent, safety-conscious workforce, which is the most critical element in achieving and sustaining long-term safety excellence in the semiconductor industry.

Consulting Services for Employee Safety in Semiconductor Manufacturing:

Safety Culture Assessment and Improvement:

-

Evaluating the existing safety culture within the organization.

-

Developing and implementing strategies to foster a strong safety culture, including leadership engagement and employee empowerment.

Comprehensive Safety Program Development and Implementation:

-

Designing and implementing customized safety programs aligned with OSHA regulations, SEMI standards, and industry best practices.

-

Developing written safety plans, including emergency response, hazard communication, and respiratory protection programs.

-

Establishing safety committees and employee participation initiatives.

Hazard Identification and Risk Assessment:

-

Conducting thorough risk assessments for chemical, physical, ergonomic, and other hazards specific to semiconductor manufacturing processes.

-

Implementing hazard control measures, including engineering controls, administrative controls, and PPE selection.

-

Developing Job Hazard Analyses (JHAs) for critical tasks.

Chemical Safety Management:

-

Developing and implementing chemical hygiene plans.

-

Assisting with the safe handling, storage, and disposal of toxic, corrosive, and flammable materials.

-

Designing and evaluating ventilation systems for chemical exposure control.

-

Implementing emergency spill response procedures.

Incident Investigation and Root Cause Analysis:

-

Developing procedures for investigating incidents and near misses.

-

Training personnel on root cause analysis techniques to prevent recurrence.

"In manufacturing, precision and efficiency builds products — but safety builds futures. A strong safety mindset isn’t just compliance, it’s commitment: to every hand on the line, every shift, and every life behind the machinery. When safety is woven into the fabric of our work, we don’t just meet production goals — we protect what matters most. Because the real measure of success isn’t just what we make, but how safely we make it."

Navigate semiconductor safety with confidence. Optimize 360 provides expert consulting and tailored training, empowering your workforce and fostering a lasting culture of safety. Our experienced professionals understand the industry's unique hazards, offering comprehensive support from risk assessments to specialized, beyond-compliance training.

Invest in your people and safeguard your operations with us to build a resilient safety framework that minimizes risks, enhances productivity, and ensures long-term sustainability.